Cómo Puerto Rico está impulsando la innovación en el sector de manufactura avanzada

Puerto Rico’s manufacturing sector has long been the backbone of the island’s economy, generating nearly half of its GDP and establishing the island as a global leader in pharmaceuticals, medical devices, and advanced manufacturing. However, Puerto Rico isn’t resting on its laurels—it’s embracing cutting-edge technologies like artificial intelligence (AI) and automation to ensure it stays ahead of the curve. In an era where adaptability drives success, Puerto Rico’s manufacturing industry continues to evolve and innovate, creating a supportive environment for companies looking to grow and succeed.

A Legacy of Manufacturing Excellence

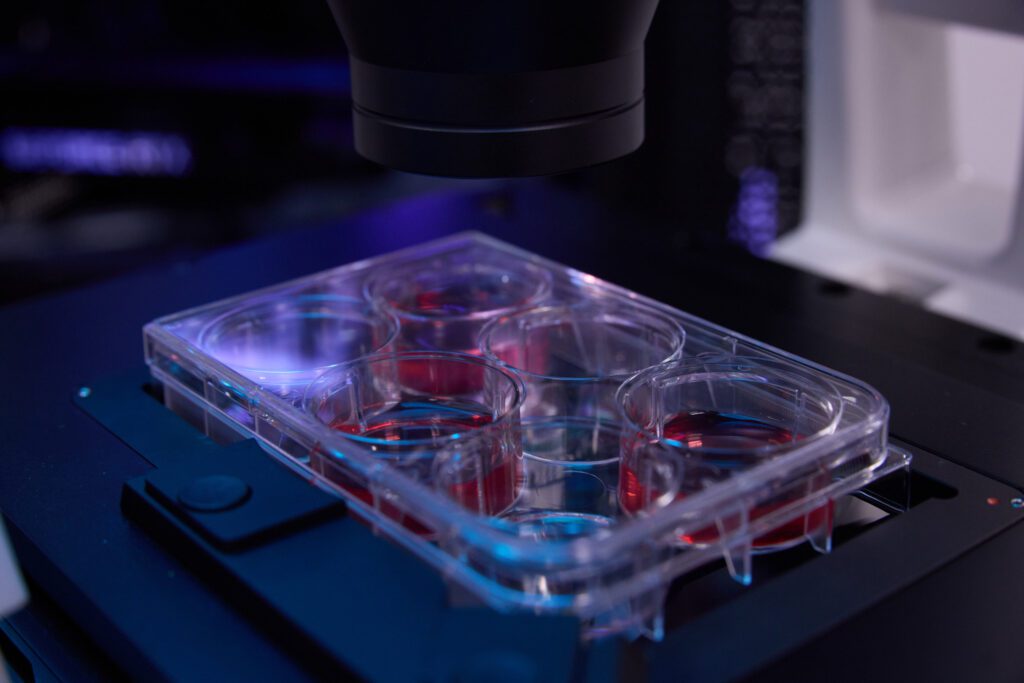

With more than 70 years of proven experience in manufacturing, Puerto Rico has built a world-class ecosystem supported by infrastructure, skilled talent, and strategic location. The island is home to 5 of the top 10 biopharmaceutical companies, manufacturing 6 of the 10 top-selling drugs worldwide. Additionally, over 30 medical device companies operate on the island, producing high-quality, life-saving products that meet the rigorous standards of U.S. and international regulators.

Beyond pharmaceuticals and medical devices, Puerto Rico is a rising force in electronics, aerospace, and biotechnology. Global leaders like Amgen, Pratt & Whitney, and CytoImmune Therapeutics have established or expanded their operations on the island, tapping into Puerto Rico’s competitive advantages:

- Skilled STEM workforce

- World-class infrastructure

- Strategic location with access to U.S. and Latin American markets

- Generous tax incentives

- Pro-business environment

Embracing AI & Automation: The Future of Manufacturing

The local manufacturing sector is not just keeping pace with technological change—it’s leading the charge. Companies on the island are increasingly adopting AI-powered tools and automation to boost productivity, optimize operations, and enhance innovation. For example, leading biotech company Amgen recently achieved an industry first: the first fully validated visual inspection system using AI. The project involved retrofitting a Syntegon syringe inspection machine at Amgen’s Juncos production facility with deep learning technology. The machine, which has 13 inspection stations, encountered an industry-wide challenge: differentiating between air bubbles in injectable solutions and unwanted particles that signal product defects. The AI system significantly increased particle detection accuracy by 70% while reducing false detections by 60%, optimizing both safety and operational costs.

Meanwhile, automation is becoming the standard across industries. At Orlando Health’s Robotic Surgery Center in Dorado, surgeons are using advanced robotic systems to perform minimally invasive procedures with greater precision, enhancing control during surgeries and reducing fatigue. These robotic tools not only improve patient outcomes but also allow for faster recovery times, making healthcare more efficient and effective.

Puerto Rico’s dynamic environment has drawn new arrivals like Hemostemix and Smartweave, two companies at the forefront of cutting-edge developments in life sciences and AI. Hemostemix, a Canadian company specializing in autologous stem cell therapies, recently partnered with CytoImmune Therapeutics to establish production at its Toa Baja facility. This collaboration marks the first commercial manufacturing of cellular therapies in Puerto Rico, expanding the island’s biopharmaceutical sector into new areas like treatments for chronic limb ischemia and heart disease.

For its part, Smartweave, a Boston-based regenerative therapeutics and device design company, has chosen Puerto Rico for its research and manufacturing center at the Forward Center of the Science, Technology and Research Trust in San Juan. Smartweave specializes in personalized solutions for connective tissue restoration using advanced technologies, such as AI-powered digital twins and 3D biofabrication.

In a different arena, AI-powered cleaning robots at the Luis Muñoz Marín International Airport autonomously sweep, mop, and vacuum over one million square feet of flooring. These robots ensure the airport maintains top-tier cleanliness standards while managing the demands of over 12 million annual passengers. By reducing the need for manual labor in routine tasks, the airport optimizes operations, demonstrating how automation can address labor shortages across essential services.

Investments That Spur Growth

Substantial investments from companies and government initiatives play a key role in the island’s ever-evolving manufacturing sector. One example is Medtronic’s $50 million expansion at its Juncos facility. This project will create 700 jobs—200 during construction and 500 permanent roles—and enhance the production of glucose sensors for diabetes patients. The company has converted 11,000 square feet of office space into a manufacturing plant capable of producing 15 million sensors annually, reflecting Medtronic’s commitment to both Puerto Rico and cutting-edge medical innovation. Similarly, Stryker is investing $58.6 million to construct an Innovation Center and expand its operations, adding over 200 well-paying jobs. The investment will also support the launch of 12 new products.

Beyond private-sector investments, Puerto Rico’s Department of Economic Development and Commerce (DDEC, its Spanish acronym) is boosting the life sciences sector through workforce development initiatives. The DDEC has allocated $2 million to support training and certification programs as part of the 21st Century Techforce initiative. These efforts focus on building a talent pool in biopharmaceuticals, biotechnology, automation, and robotics, ensuring that the island’s workforce can meet the demands of advanced manufacturing. The initiative includes collaborations with companies like Ultimate Solutions Corp., which will double the number of participants trained in AI and robotics annually, and C3Tech’s Bioprocessing Center, which offers biotechnology certifications and mentoring programs to more than 400 students annually.

Also, targeted programs like Invest Puerto Rico’s Workforce Compass and the DDEC’s BioInnovate help companies grow with access to skilled professionals and cutting-edge training. Workforce Compass provides concierge-level support to employers, connecting them with local universities, training providers, and specialized talent pools. This “white glove” service streamlines recruitment by helping businesses create custom training programs tailored to their needs, especially in high-demand fields like AI, automation, cybersecurity, and biotechnology.

BioInnovate supports workforce development by offering short-term credentialing and job training programs in fields like advanced manufacturing, automation, and research & development. These programs align with industry needs and provide grants of up to $400,000 to educational providers and employers, helping to build the technical capabilities necessary for companies to thrive.

By combining tailored workforce solutions with targeted industry training, Puerto Rico empowers companies with a future-ready workforce and the innovation ecosystems they need to grow and succeed.

Da el paso

If you’re looking for a dynamic location to manufacture, innovate, and thrive, look no further than Puerto Rico—where the future of manufacturing is already happening.

It’s not what’s next. It’s where.

Puerto Rico.